I’ve always been fascinated by how quartz keeps its cool under extreme heat. It’s like the material has a built-in superpower. I want to share a simple, clear explanation of why quartz’s structure makes it so darn heat-resistant.

When people ask, “What structural property makes quartz heat resistant?” here’s the short answer: Quartz features a tightly bonded crystalline framework of silicon dioxide molecules, which gives it remarkable stability at high temperatures. This unique arrangement minimizes expansion under heat and reduces the risk of cracking or deforming.

I’d love to dig deeper into the fascinating details.

Quartz Crystal Structure: The Key to Heat Resistance

Quartz’s crystal lattice might sound a bit abstract, but it’s essentially a rigid network of silicon and oxygen. Just think of it like an elaborate interlocking puzzle, where each piece fits neatly without gaps.

Quartz owes its heat resistance to its stable lattice of SiO₂ molecules. These molecules form a three-dimensional framework that disperses heat evenly and prevents excessive expansion. That’s why quartz can withstand sudden temperature changes that might ruin lesser materials.

I’ve often compared quartz’s architecture to a medieval fortress: its walls are tough, and the design is built to last. Let’s unpack the details:

Lattice Arrangement

The crystal structure of quartz is made up of repeating units of silicon-oxygen tetrahedra—each tetrahedron has one silicon atom bonded to four oxygen atoms. These tetrahedra share oxygen atoms with neighboring tetrahedra, creating a dense network with very few “weak links.”

Why Density Matters

Denser bonding means fewer spaces for heat to wiggle in and cause abrupt changes in shape. In simpler terms, if you heat quartz, its atoms can handle it because they’re already locked tightly. This arrangement helps reduce internal stress and cracking—imagine how a snug group of friends can brace each other against sudden pushes and pulls.

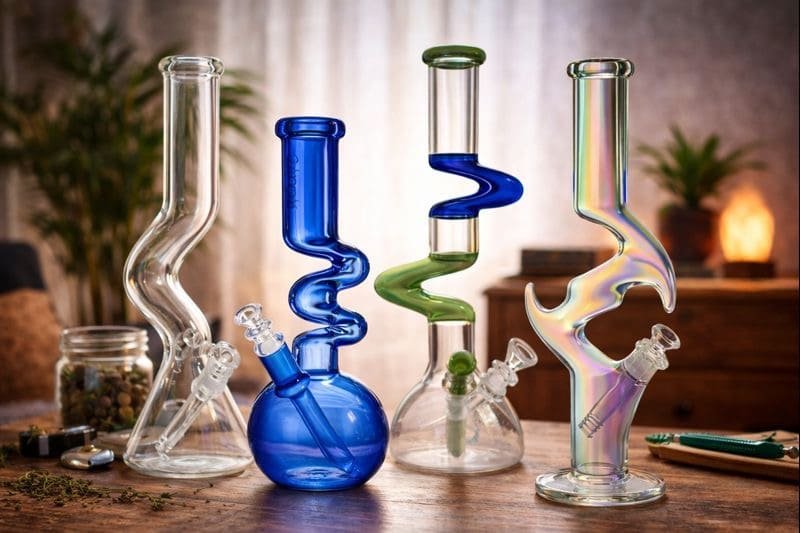

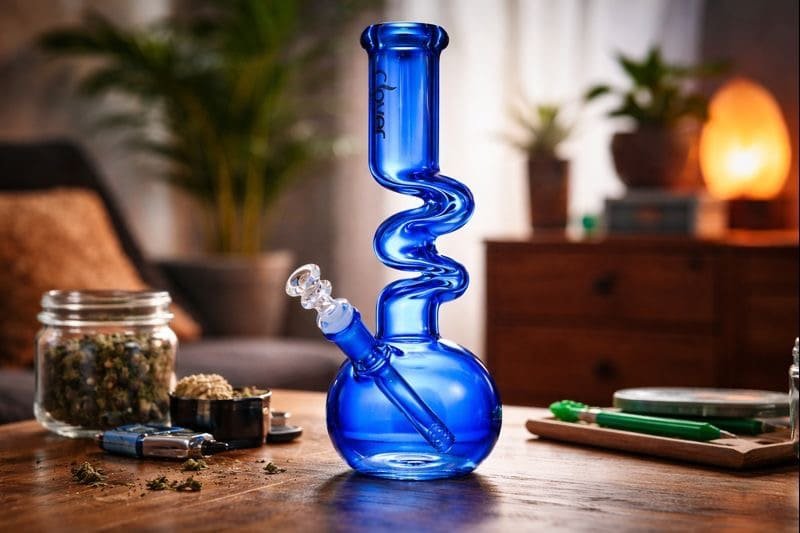

Impact on Our Glass Products

As someone who runs CloverGlass (my B2B glassware brand), I see quartz’s benefits daily. We use quartz elements for certain smoking accessories, especially where high heat is inevitable, such as quartz bangers and nails for dab rigs. The crystal structure resists cracking when people torch them repeatedly, saving them from unwanted breakage.

In my experience working wholesale for customers all over the United States, consistent quality is king. Having quartz in our product line gives me the confidence to promise reliability. And yes, that’s exactly what keeps customers coming back, whether they’re wholesalers, distributors, or local smoke shop owners.

Silicon-Oxygen Bonds: The Secret Behind Quartz’s Thermal Stability

These Si-O bonds in quartz are famously strong. It’s like having a million tiny welded joints that refuse to break, even when the temperature cranks up.

Each silicon atom is linked to oxygen atoms, forming a robust tetrahedron. Because silicon and oxygen form one of the strongest chemical bonds around, quartz can handle high temperatures without losing its shape. That’s the core reason why quartz stays stable when the heat is on.

When you have a chain of strong links, it’s tough to break them—even under stress. That principle holds true for quartz’s molecular bonds, which serve as the bedrock of its heat-resistant reputation.

Molecular Resilience

Si-O bonds are significantly stronger than most metal-oxygen bonds. This resilience is what helps quartz avoid melting or warping at temperatures that would annihilate ordinary glass. Because my team has been in the glass industry for over a decade, I appreciate how this strength translates to fewer product defects.

Real-Life Application

Think about how you can rapidly heat a quartz nail with a torch, then let it cool, only to reheat it moments later. Those strong Si-O bonds handle that stress repeatedly. In more conventional glasses, you’d see cracks forming over time. This difference can be a deal-breaker for serious users who need equipment to last.

Combining Bonds With Good Service

From a practical standpoint, if someone’s ordering a big batch from our Los Angeles warehouse, I know it’ll get delivered intact thanks to robust packaging and the material’s inherent durability. The product’s lifetime also extends, giving both the distributor and the end customer a better experience.

Low Thermal Expansion: Why Quartz Resists Thermal Shock

Thermal shock can spell doom for many glass items, but quartz sidesteps that chaos by not expanding much when heated. Small expansions mean fewer cracks.

Quartz boasts a notably low coefficient of thermal expansion. In other words, its dimensions barely change, even when exposed to high heat. This keeps internal stresses in check, helping quartz withstand sudden temperature swings like a pro.

Think about what happens to a balloon when you blow it up rapidly—it expands and might pop. Materials with high thermal expansion do something similar under heat. Quartz, on the other hand, doesn’t “inflate” much at all when it gets hot.

Explaining Thermal Shock

Thermal shock occurs when a material experiences a drastic temperature change, causing different parts to expand or contract unevenly. In materials with a high expansion rate, these internal differences can create fractures. Quartz avoids that big difference entirely.

Why It Matters for CloverGlass Products

Our bongs, dab rigs, and other smoking accessories endure fast temperature fluctuations: one second, they’re room temperature; the next, they’re engulfed in scorching heat. If these items expanded too much, they’d be at risk of shattering. Low expansion helps ensure their longevity. That means fewer returns, fewer sad phone calls from distributors, and a happier chain of businesses.

From Production to Delivery

We produce items in our Chinese factory and keep stock in our LA warehouse. Because quartz is less prone to random cracks due to shipping jostles or temperature changes en route, we can be more flexible with shipping methods, thus saving costs. After all, damaged goods aren’t beneficial for anyone in the supply chain.

Quartz Glass vs. Regular Glass: How Structure Affects Heat Resistance

You might think all glass is created equal, but quartz glass is worlds apart from the usual stuff we see in windows or basic kitchenware.

Regular borosilicate glass or soda-lime glass usually can’t match quartz’s high-temperature tolerance. The difference lies in the molecular structure and purity. Quartz glass is nearly pure SiO₂, with stronger bonds and lower expansion rates—making it far more resilient under heat stress.

Not all glass is the same, even though we use one word—“glass”—to describe them. The composition and structure can vary significantly.

Ingredient Differences

- Quartz Glass: Almost 100% silicon dioxide. This purity yields a tightly bonded structure and minimal expansion.

- Regular Glass (e.g., Soda-Lime): Generally has added sodium, calcium, and other impurities. These additions lower melting points but also reduce thermal stability.

| Type of Glass | Composition |

|---|---|

| Quartz Glass | ~99%+ SiO₂ |

| Borosilicate Glass | Around 80% SiO₂, plus boron trioxide |

| Soda-Lime Glass | About 70% SiO₂, plus sodium oxide |

Practical Consequences

When I’m working with quartz glass, I know it’ll survive much harsher heating conditions. On the flip side, typical glass might get the job done in your windowpane, but it won’t stand up to a propane torch as valiantly.

Business Edge

By offering quartz accessories, I’m able to supply my U.S. customers—large smoke shops, boutique distributors, brand owners—with products that reliably handle intense heat. That reliability often cuts down on returns and complaints. A side benefit? It boosts my reputation for quality. They know that if something is labeled “quartz” from our brand, it’s meant to last.

The Role of Chemical Purity in Quartz’s Heat Resistance

Purity matters for more than just bragging rights. The fewer impurities there are in quartz, the fewer weak spots there are for cracks to form.

High-purity quartz has minimal contaminants, which means there’s nothing to disrupt the tightly woven Si-O network. The result is robust, uniform material that holds steady under high temperatures. Impurities can create stress points and lower the melting threshold.

It might sound strange that tiny amounts of different elements can sabotage an otherwise rock-solid material. But any foreign element squeezed into a crystal structure can create pockets of instability.

Contaminants as Flaws

Let’s say trace metals or other compounds sneak their way in. These contaminants often expand at different rates than the surrounding silicon dioxide. That leads to micro-stress regions, making the quartz more vulnerable to thermal shock. In simpler terms, a single bad apple can spoil the barrel.

Selecting the Right Raw Materials

At CloverGlass, we’re careful about sourcing raw quartz for special lines of nails, bangers, or any part that endures direct flame. Reliable suppliers and stringent quality checks ensure consistency. That consistency is crucial for large-scale orders—when a distributor is buying 20 boxes or an entire pallet, they expect uniform performance across the board.

Keeping Customers Happy

Ultimately, purity keeps breakage rates low. If you’re a wholesaler catering to demanding clients in places like California, Oregon, or even overseas, consistent quality is gold. They want top-tier products that won’t fail under normal (or even slightly abusive) use. Achieving that mostly comes down to carefully selected, pure quartz stock.

How Quartz Performs in High-Temperature Applications

Quartz isn’t just for dabbing or home décor. It has a starring role in some of the world’s hottest industrial and scientific settings.

Thanks to its rigidity, low thermal expansion, and robust bonds, quartz keeps its form even at temperatures above 1000°C. Whether it’s a furnace window, lamp tube, or specialized lab equipment, quartz excels because it doesn’t soften quickly, reducing the risk of structural failure.

There’s a good reason laboratories, semiconductor manufacturers, and specialized industries rely on quartz. It’s built to endure extremes without a hitch.

Industrial Furnaces

In many industrial furnaces, quartz windows let workers observe processes at temperatures that would melt other glass. The quartz remains optically clear and doesn’t distort. That clarity can be crucial for monitoring everything from metal forging to chemical reactions.

Specialized Lighting

Some high-intensity lamps, including certain UV lamps, use quartz tubes because of their ability to handle intense heat. Quartz’s transparency to UV light adds another layer of benefit in scientific or disinfection applications. If standard glass were used, it might crack or even block out essential UV wavelengths.

Smoking Accessories and Beyond

Of course, I see quartz’s value every day in the smoking accessories world. But that’s just a fraction of its story. Because our brand focuses on B2B wholesale, we often hear from other industries looking for specialized quartz solutions. Whenever you need a material that won’t flinch under blistering heat, quartz is the one to call.

My Service Promise

I learned firsthand that maintaining high standards in quartz products can revolutionize a distributor’s business. That’s why we keep a large inventory in our U.S. warehouse. Shipping is faster, the cost is more manageable, and we offer professional after-sales support if anything goes wrong in transit. If something does break or gets held up at customs, I’ve got a team to resolve it. Nobody enjoys waiting around for a fix; it’s all about swift, reliable service.

Conclusion

Quartz’s heat resistance boils down to its rock-solid lattice of silicon and oxygen, its incredible purity, and its low expansion rate. When a material is built this sturdily, it’s no wonder it holds strong under extreme temperatures—no cracking, no fuss, just solid performance.