Worried that “China glass” means cheap or risky? Confused by mixed opinions online?

Many buyers hesitate because they don’t know how China glass is actually made, graded, and sourced for real-world use.

China glass refers to glass products manufactured in China, including glass bongs, using a wide range of production methods—from basic mass production to high-skill handmade work. For glass bong importers, it’s less about origin and more about process control, materials, and quality standards.

I’ve worked with China glass for over a decade, so let me break it down clearly.

What Does “China Glass” Mean in the Glass Bong Industry?

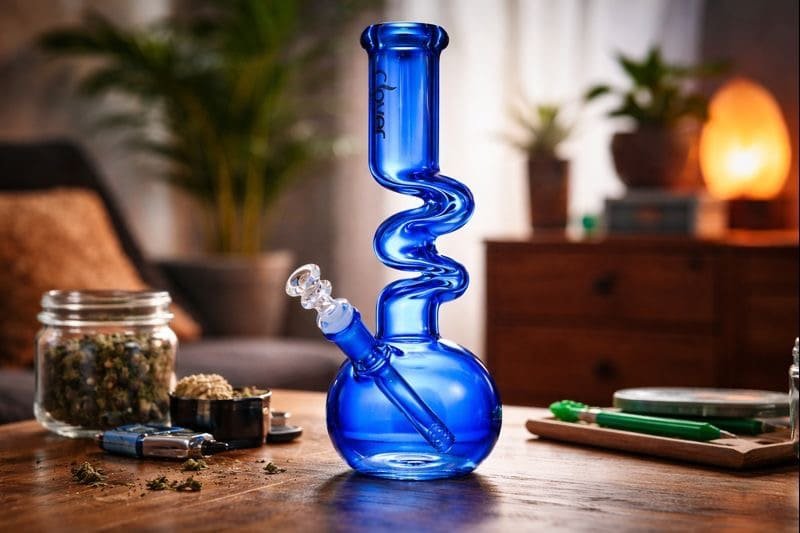

China glass simply means glass products made in China, but in the bong industry it usually refers to factory-produced glass bongs designed for scalability, consistent specs, and wholesale distribution.

In the glass bong world, “China glass” is not a material. It’s not a single quality level either. It’s a shorthand buyers use to describe bongs produced by glass manufacturers in China, often at scale, with repeatable designs and standardized joints.

When customers ask me, “Frank, is this China glass?”, what they’re really asking is:

Was this made in a factory instead of a small U.S. studio?

That’s the key distinction.

China glass bongs usually come from organized workshops or factories. These facilities focus on consistency—same joint size, similar wall thickness, predictable airflow. That’s why most glass bong importers rely on them. Retail shelves need repeatable products, not one-off art pieces.

I still remember my first U.S. buyer visit years ago. He picked up two identical beaker bongs and said, “These feel the same.” That was the point. Consistency builds trust at retail.

China glass is also closely tied to glass manufacturing in China, where supply chains for tubing, color rods, and annealing ovens are centralized. This ecosystem allows faster production cycles and easier restocking.

China glass vs. “artisan glass”

China glass emphasizes:

- Repeatable designs

- Scalable output

- Wholesale pricing

Artisan glass emphasizes:

- Individual expression

- One-off pieces

- Collector value

Neither is “better” universally. They serve different buyers.

Is China Glass Low Quality or Just Mass-Produced?

China glass is often mass-produced, but mass production does not automatically mean low quality—quality depends on materials, annealing, and QC, not geography.

This is the biggest myth I see online. “Mass-produced” sounds negative, but for most consumer goods, it’s exactly what ensures stability.

Low quality China glass does exist. So does low quality glass made anywhere else. The difference is that China has layers of quality, from entry-level to very refined.

In our factory, we run annealing cycles on every glass bong. That step alone eliminates many cracking issues. Without proper annealing, even thick glass can fail due to internal stress.

From my experience, quality issues usually come from:

- Skipped annealing to save time

- Inconsistent wall thickness

- Poor joint alignment

Those are process problems, not “China” problems.

For glass bong importers, the real question should be:

What QC steps does this manufacturer follow?

In CloverGlass, we inspect joints, bases, and weld points. If there’s an issue, our after-sales policy is simple: photo → credit. That’s how B2B trust works.

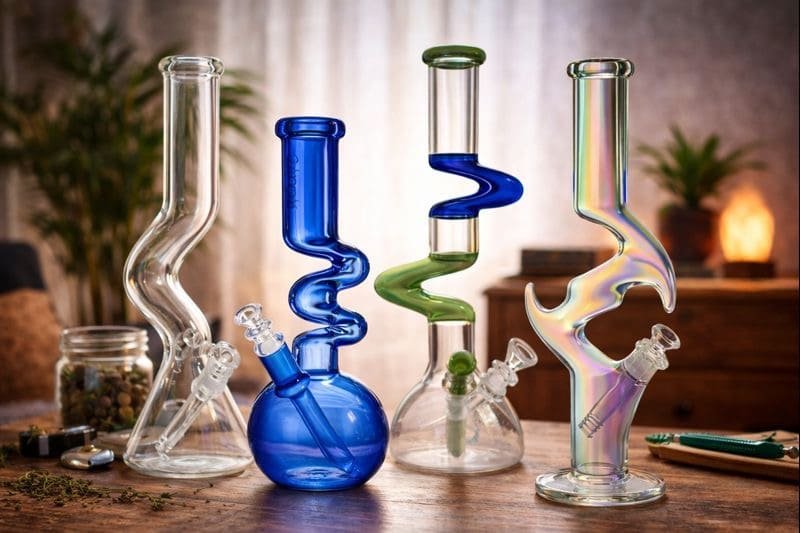

Common quality tiers you’ll see

- Entry-level: thinner glass, simple shapes

- Mid-tier: thicker walls, better balance

- Functional/premium: recyclers, multi-perc designs

What mass production does well

Mass production ensures:

- Predictable fit with bowls and downstems

- Easier replacement and reorders

- Lower breakage variance

That’s why most smoke shops rely on it.

How Is China Glass Made Compared to U.S. or EU Glass?

China glass is typically made through a hybrid process—hand-blown steps combined with standardized tooling—while U.S. and EU glass often emphasizes individual craftsmanship.

This comparison comes up a lot. I’ve visited small U.S. studios and large Chinese factories. The difference is not skill—it’s workflow.

In China, glass manufacturing is organized. One team handles tubing prep. Another handles welding. Another focuses on annealing and QC. This division of labor speeds things up.

In the U.S. or EU, a single artist may do everything start to finish. That’s beautiful, but slower and harder to scale.

From a buyer’s perspective:

- China glass = repeatability

- U.S./EU glass = individuality

Neither approach is wrong.

I once timed OEM production for a custom beaker run. In China, we finalized samples in days and completed production in about 20–25 days. That timeline is hard to match elsewhere at scale.

Materials used

Most China glass bongs use borosilicate glass tubing, similar to what’s used globally. The difference is sourcing efficiency.

Why importers care

Glass bong importers care about:

- Lead times

- Unit consistency

- Packaging compatibility

China manufacturing aligns well with those needs.

Why Do Most Glass Bong Importers Source from China?

Most glass bong importers source from China because it offers the best balance of cost control, production scale, and design variety for retail businesses.

This is where reality beats theory.

If you’re running a smoke shop or online store, you need:

- New designs regularly

- Predictable margins

- Reliable restocks

China delivers that combination.

Another factor is infrastructure. Glass manufacturers in China are clustered. Color rods, quartz, packaging—all nearby. That reduces delays.

For U.S. buyers, logistics also matter. That’s why we built our LA warehouse. Popular items ship fast domestically, while factory-direct orders support broader selection.

Cost is not the only reason

Yes, pricing matters. But importers also value:

- OEM flexibility

- Custom packaging

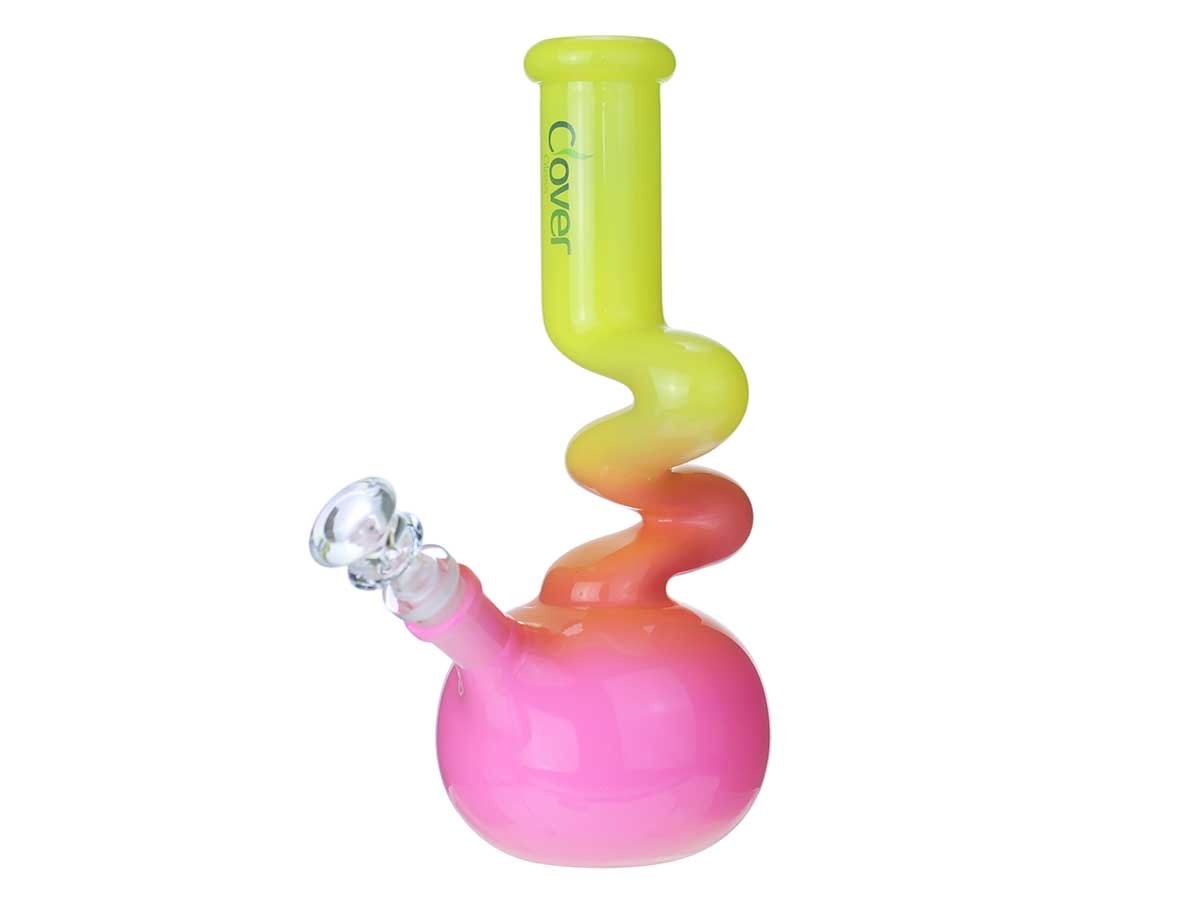

- HD product images for listings

Risk management

With the right partner, risks are manageable. We handle customs issues and compensate if goods are detained or lost. That’s critical for first-time buyers.

What Should Importers Know Before Buying China Glass Bongs?

Before buying China glass bongs, importers should evaluate annealing, wall thickness, joint specs, packaging, and after-sales policies—not just price.

This section is where buyers avoid mistakes.

Here’s a practical checklist I often share:

- [ ] Ask about annealing process

- [ ] Confirm joint size (14mm / 18mm)

- [ ] Check base stability

- [ ] Review packaging method

- [ ] Clarify breakage policy

Skipping these steps leads to problems later.

One buyer once ordered cheap bongs elsewhere without packaging specs. Breakage rate was high. He switched suppliers—not because of price, but because of after-sales support.

Cleaning & heat safety notes

For consumers, over-heating bowls or rapid temperature changes can cause cracks. Educating end-users helps reduce returns.

OEM expectations

OEM doesn’t mean instant. Standard OEM lead time is usually 20–25 days after sample approval. Planning matters.

Is China Glass Right for Your Smoke Shop or Wholesale Business?

China glass is ideal for smoke shops and wholesalers that prioritize consistency, scalable supply, and competitive pricing—but it may not suit collectors seeking one-of-a-kind art pieces.

This is the final decision point.

If your business relies on:

- Repeatable SKUs

- Predictable margins

- Broad customer appeal

Then China glass bongs make sense.

If you’re targeting collectors or gallery buyers, you may want artisan glass alongside China glass.

Most successful shops I know do both.

My honest take

China glass is a tool. Used correctly, it supports growth. Used blindly, it causes frustration. The difference is supplier choice.

Conclusion

China glass is not a shortcut—it’s a system. For glass bong importers, understanding how glass manufacturing in China works helps you choose better products, reduce risk, and scale with confidence. When sourced responsibly, China glass bongs serve both retailers and end consumers well.

Get wholesale quote | Order Online: https://cloverglasspipe.com/order-glass-smoking-products-online/ | Email Frank

FAQ

Q1: Is China glass safe to use?

A1: China glass bongs made from borosilicate glass and properly annealed are safe for normal use. Safety depends on manufacturing process and QC, not country of origin. Avoid overheating and sudden temperature changes.

Q2: Why are China glass bongs cheaper?

A2: Lower costs come from supply-chain efficiency, labor organization, and scale—not necessarily lower quality. Bulk production reduces per-unit cost for importers.

Q3: How can I tell good China glass from bad?

A3: Check wall thickness consistency, joint alignment, annealing information, and after-sales support. Reputable glass manufacturers in China will explain their process clearly.

Q4: Do China glass bongs break easily?

A4: Breakage usually relates to thin glass or poor annealing. Well-made China glass bongs are durable for everyday use when handled properly.

Q5: Is China glass only for wholesalers?

A5: No. Many end consumers buy China glass directly online. Wholesalers benefit most due to pricing and scale, but consumers value consistency and affordability too.

Q6: Can I customize China glass bongs?

A6: Yes. OEM options include logos, colors, and packaging. Typical OEM lead time is 20–25 days after sample approval.

Q7: Are China glass bongs mass-produced by machines?

A7: Most involve hand-blown steps combined with standardized processes. Full automation is rare for complex shapes like recyclers.

Q8: How long does shipping from China take?

A8: Factory-direct shipping usually takes 15–20 days. U.S. buyers can also use LA warehouse stock for faster delivery.

Q9: Why do U.S. shops prefer China glass?

A9: Consistent quality, easy reorders, broad design options, and stable margins make China glass attractive for retail.

Q10: Is artisan glass better than China glass?

A10: Artisan glass offers uniqueness and artistic value. China glass focuses on consistency and scalability. Many shops stock both for different customer needs.