Finding a glass‑accessories partner shouldn’t feel like rolling the dice. In the next few minutes, I’ll show you how to spot a keeper—and dodge the duds—before your next bulk order lands on the docks.

Wholesale buyers search Google every day for one thing: certainty.

They want suppliers who ship on time, pack glass that actually survives the journey, and stand up when something goes wrong. Below you’ll discover the checkpoints buyers use to separate the pros from the pretenders—so you can stock faster, sell sooner, and sleep easier.

Markets move fast. Let’s jump straight in.

What Qualifies as a Reliable Wholesale Supplier in the Smoking Accessories Industry?

A supplier earns the “reliable” badge by blending consistent quality, transparent terms, and responsive service—day after day, pallet after pallet.

Reliable wholesalers tick three boxes: predictable lead times, documented quality control, and after‑sales solutions that cost you nothing when glass breaks.

The Building Blocks of Reliability

Reliability starts with basics many sellers gloss over. Does the shop run real annealing kilns, or do they cool pieces on a steel rack and hope for the best? Are order terms posted in plain English, or buried in fine print? I insist on a signed QC checklist with every production run; it acts as a common language between buyer and blower. Ask for batch photos, too. Legit factories snap images of random samples alongside calipers and thickness gauges.

Must‑Ask Checklist

| Checkpoint | Why It Matters | Quick Test |

|---|---|---|

| Written lead‑time guarantee | Lets you plan promotions without guesswork | Request a penalty clause for late ship‑outs |

| Independent drop‑test report | Proves packaging can survive couriers | Ask for a recent PDF from SGS or BV |

| Credit‑back policy on breakage | Shields your margin from transit losses | Demand photo‑only claims—no returns |

Pro‑tip: A factory that balks at simple documentation probably cuts other corners, too.

Where Do Most Smoke Shops and Distributors Source Their Glass Products?

Nearly 70 percent of North‑American smoke shops buy from Chinese blowers, but seasoned buyers rarely import direct. They rely on importers who already warehouse stock in the U.S. or Canada.

Global sourcing still rules, yet domestic warehousing trims freight, duties, and wait times—turning a 40‑day ocean trek into a 4‑day forklift job.

Hotspots and Emerging Hubs

Glass‑blowing clusters dot Cangzhou, Hebei and Yiwu, Zhejiang. In the West, Mexico and the Czech Republic are gaining ground for borosilicate beakers. But inventory must cross oceans, clear customs, and survive long‑haul trucking. That’s why more wholesalers keep buffer stock in Los Angeles or New Jersey free‑trade zones.

Typical Flow

- Factory in Hebei fires the recycler.

- Consolidator fills a 40‑foot container.

- Freight forwarder files ISF and books a FMC‑licensed carrier.

- Container lands in Long Beach, clears CBP, and moves to an L.A. warehouse.

- U.S. distributor breaks pallets into shop‑friendly cartons.

Cutting out steps 2‑4 on repeat orders shaves at least 25 days off your shelf date.

Top Factors to Consider When Choosing a Glass Smoking Accessories Supplier

Price is loud but not lonely. Ten other levers pull profits into—or out of—your pocket.

Savvy buyers weigh total landed cost, not just FOB quotes, plus the soft factors that make business painless for years.

The Ten‑Lever Framework

| Factor | Key Question | Hidden Cost If Ignored |

|---|---|---|

| Product depth | Can I reorder next month and still get matching SKUs? | Disjointed shelf visuals |

| Warehouse location | How many zones away from my shop? | Costly two‑day air rushes |

| MOQ flexibility | Will they mix SKUs per pallet? | Over‑stock, slow cash cycle |

| Quality certification | Any ISO 9001 or CE docs? | Returns, refunds, reviews |

| Packaging strength | Drop‑test data shared? | Breakage write‑offs |

| Payment terms | Escrow? 30/70 TT? | Capital lock‑up |

| After‑sales policy | Credit or cash back? | Margin erosion |

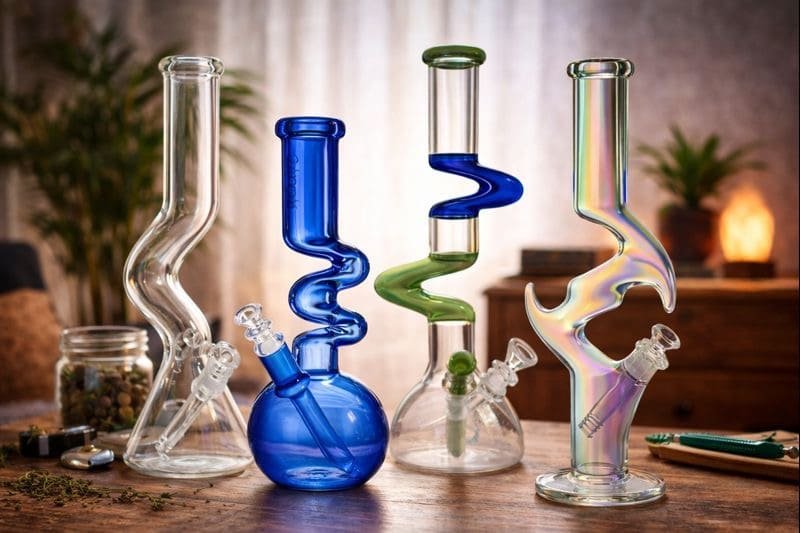

| New‑product cadence | How often do they launch fresh glass? | Lost foot‑traffic buzz |

| Marketing assets | Free HD photos? | Extra photo‑shoot spend |

| Trade‑show presence | Do they show at CHAMPS? | Harder credibility check |

Balance the ten levers. A cut‑rate price with weak packaging costs more than a premium quote that ships safe.

How to Verify Supplier Credibility and Avoid Common Pitfalls

Google the brand, sure—but real vetting goes deeper.

Cross‑verify business licenses, factory audits, and trade references before wiring that first 30 percent deposit.

Six‑Step Verification Flow

- Company Registry Search – Confirm registration on China’s National Enterprise Credit portal.

- Video Walkthrough – Request a live phone tour of the hotshop. Pause, ask to show today’s date.

- Third‑Party Audit – Book an inspection with Intertek, even on small orders; $200 now beats $2,000 later.

- Reference Calls – Email at least two U.S. buyers listed on past bills of lading.

- Sample Stress‑Test – Heat, freeze, and drop a prototype. Document with slow‑mo video.

- Secure Payments – Use Alibaba Trade Assurance or a bank L/C until trust is earned.

Avoid the classic pitfall of chasing rock‑bottom quotes advertised on social media. Many are resellers with no control over production.

Why U.S.-Based Warehousing and Fast Shipping Are Game Changers for Retailers

Every extra day in transit is a day without revenue. Local stock flips that script.

A stateside warehouse slashes lead times from weeks to days and lets you replenish by the pallet—without gambling on customs delays.

Speed vs. Cost: The Freight Equation

| Route | Transit Time | Typical Cost per Kg | Risk Level |

|---|---|---|---|

| Factory → Ocean → Smoke Shop | 35–45 days | $1.60 | High (customs, breakage) |

| Factory → L.A. Warehouse → Smoke Shop | 14–20 days | $2.10 | Medium (one customs entry) |

| L.A. Warehouse → Smoke Shop | 3–5 days | $0.90 | Low |

Notice how the in‑country leg is cheapest. That’s the hidden upside of importers who pre‑clear bulk stock and store it near port. It also unlocks Just‑In‑Time restocks during holidays when cash flow matters most.

Should You Go With OEM, ODM, or In‑Stock Glass Smoking Products?

Your growth stage decides the answer.

OEM gives you full control, ODM offers semi‑custom quick wins, and in‑stock SKUs keep shelves full while the first two bake.

Production Models Demystified

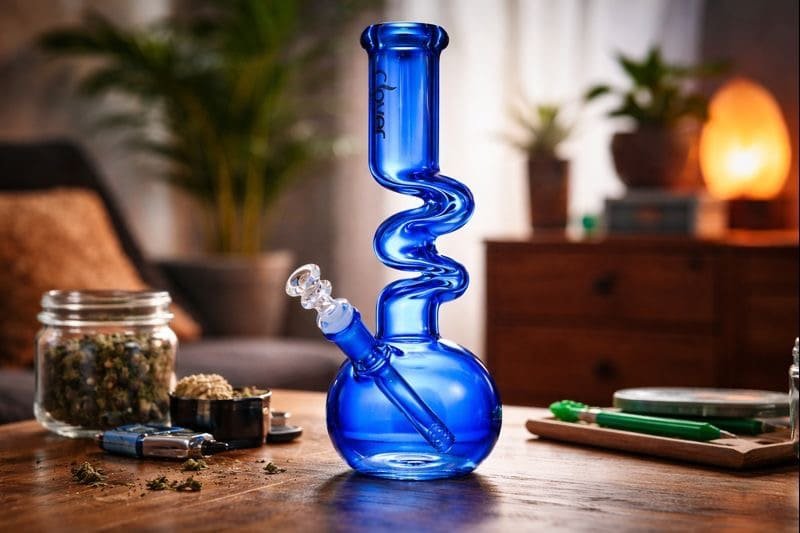

- In‑Stock – Ready‑made, ready‑to‑ship. Perfect for testing new flavors of demand or filling sudden gaps.

- ODM (Original Design Manufacturer) – Factory tweaks an existing mold, slaps on your logo, and pours out mid‑range volumes fast. Think seasonal color runs.

- OEM (Original Equipment Manufacturer) – Full‑custom tooling, unique percs, or wild shapes straight from your CAD file. Requires patience—and deep pockets—but locks in a moat your rivals can’t cross.

Decision Table

| Scenario | Best Fit | Typical MOQ | Lead Time |

|---|---|---|---|

| Launching first shop | In‑Stock | 20 boxes | 1 week |

| Adding brand identity | ODM | 100 pcs | 25 days |

| Patented flagship line | OEM | 500–1,000 pcs | 45 days |

Still torn? Start with in‑stock cartons to generate cash, roll profits into an ODM pilot, then graduate to OEM once sell‑through data supports the plunge.

Conclusion

Reliable glass suppliers aren’t unicorns—they’re simply the firms that prove consistency up front and stay transparent when hiccups hit. Follow the checks above, and you’ll never settle for “good enough” glass again.