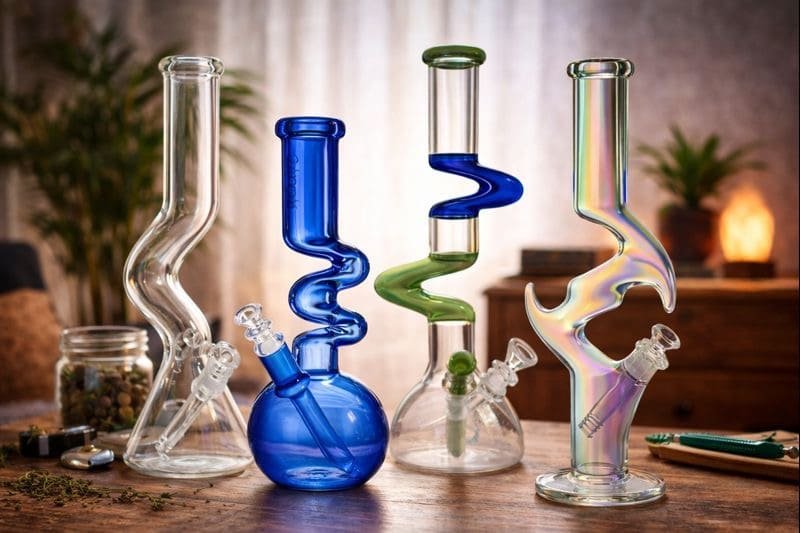

America glass bongs wow with museum-level artistry; China balances quality, price & OEM speed; India wins on ultra-low cost but trails in finish.

Below is my expanded field report—tests, QC notes, anecdotes—so your shop picks the right SKUs and avoids costly returns.

American Glass Bongs: Artistic but Expensive?

American glass bongs showcase unmatched color palettes and sculptural detail, yet studio production pushes prices into collector territory.

When I unboxed a UV-reactive dragon bong from a Seattle artist last year, the 9 mm walls, hollow horns, and sand-blasted scales screamed gallery piece. But its \$1 200 tag also meant it sat in our display case for four months before the right collector visited.

| Metric | American Glass |

|---|---|

| Color options | 🌈 Ultra-vibrant NorthStar, Greasy, Illuminati |

| Craft detail | Carved horns, hand-sculpted animals |

| Glass thickness | 7–9 mm (heavy) |

| Price range | \$500–\$2 000+ |

| Ideal for | Collectors, boutique headshops |

Stockist Checklist

- [ ] Verify kiln-annealing temp ≥ 1050 °F

- [ ] Ask for 360° HD weld photos

- [ ] Budget for low MOQs & higher ticket value

The Color Science Behind U.S. Rods

American blowers favor rare earth or silver fume rods producing neon pinks, CFL shifts, and UV pops. These rods cost up to \$300 / lb—10× standard China pricing—because the glass is small-batch and chemistry-precise. The result is color saturation that jumps off the shelf under black-light displays, turning functional glass into conversation art.

Resale Value & Collector Market

Collectors track individual artists on Instagram and Discord auction rooms. Limited runs often appreciate 15–30 % yearly if the maker gains fame. Offering a few signature U.S. pieces signals your shop’s authority and can pull in high-spend customers who later add daily-driver bongs to their cart.

Maintenance & Handling Tips

- Avoid thermal shock: let glass cool below 250 °F before rinsing.

- Use 99 % ISO only—harsh detergents dull fume colors.

- Display LEDs below 5 W to prevent heat fade over months.

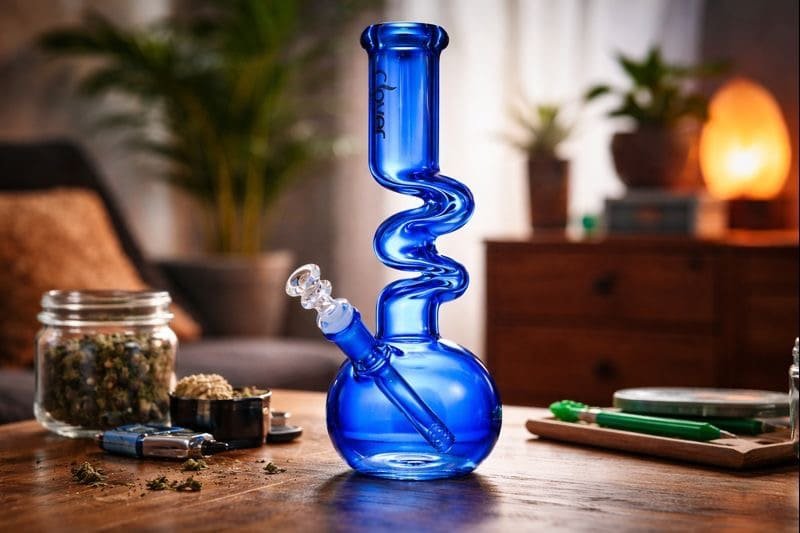

China Glass Bongs: The Best Balance?

Chinese bongs hit the sweet spot—5-9 mm borosilicate, endless OEM tweaks, and LA stock that lands within a week at mainstream prices.

Our CloverGlass warehouse moves six pallets weekly: recyclers, beakers, glycerin-coil freezables. Breakage claims average just 1.7 %, thanks to 7 mm walls and our “photo → credit” after-sales guarantee.

| Metric | China Glass |

|---|---|

| Color options | 80 % of U.S. palette + milk reds & CFL clones |

| Craft detail | Precision-cut joints, laser logos |

| Glass thickness | 5 / 7 / 9 mm |

| Price range | \$40–\$150 wholesale |

| Ideal for | Everyday users, private-label brands, distributors |

Best-Seller Mix

- 40 % straight tubes 7 mm

- 35 % recycler rigs 5 mm

- 25 % themed novelty shapes

OEM Workflow: 6 Simple Milestones

- Design brief – logo + shape in AI/PDF.

- Virtual mock-up – 48 h turnaround.

- Pre-production sample – 5 days.

- Mass blow & anneal – 15 days.

- QC & HD photo pack – 2 days.

- Ocean or LA stock shipment – 3–20 days.

Tip: Batch size ≥ 100 pcs per SKU unlocks free packaging design.

Quality-Control Playbook

- Polarized-light test each joint for stress lines.

- Drop-ball test: 240 g steel ball from 30 cm—7 mm passes 9/10 hits.

- Random torch cycle: 30 s heat, 60 s cool, repeat 3× to mimic heavy dab use.

Failures < 3 % trigger full re-blow at factory’s cost.

Shipping & Warehousing Hacks

- LA warehouse: replenish best-sellers in 48 h via UPS.

- Ocean pallet: \$600 / CBM saves 35 % vs air if lead-time allows.

- Cluster SKUs by joint size (14 mm or 19 mm) to simplify replenishment.

India Glass Bongs: Cheapest Option, But Quality?

Indian bongs slash costs by using 3 mm borosilicate and lower-grade color rods—fine for bargain bins, risky for premium shelves.

I ordered 100 pieces from Mumbai: bright teal tubes, heavy feel. Twelve percent arrived with bubbles in percs; three fractured after a single butane-torch session at ~450 °F.

| Metric | India Glass |

|---|---|

| Color options | Wide yet muted; occasional bubbling |

| Craft detail | Basic percs, rough welds |

| Glass thickness | ≈3 mm |

| Price range | \$15–\$40 wholesale |

| Ideal for | Budget packs, festival vendors |

Typical Glass Composition & Heat Limits

Most Indian plants blend soda-lime with low-grade borosilicate to cut cost. Softening point drops to ~490 °C vs 560 °C for true boro. Result: repeated torch use induces micro-fractures. If you must stock them, market as dry-herb only bongs, not torch-heavy dab rigs.

Common Defects & Workarounds

| Defect | Quick Inspection Tip | Possible Fix |

|---|---|---|

| Weld bubbles | Hold to bright LED; look for lensing | None—reject |

| Off-angle joint | Roll on flat glass; wobble means mis-seat | Sand joint (adds cost) |

| Thin base | Tap test; tinny ring = thin | Sell with silicone sleeve |

A 10 % reject buffer is prudent when placing orders.

When Does India Make Sense?

- Flash sales / sub-\$30 price tier to lure first-time buyers.

- Festival pop-ups where loss/theft risk is high.

- Backup inventory when freight budgets crash.

Do not rely on Indian SKUs for branded OEM lines; QC swings make brand consistency impossible.

Conclusion <

| Goal | Best Source | Rationale |

|---|---|---|

| Curated art, high ticket | America | Unique colors, signature artists |

| Everyday quality + OEM | China | 7 mm strength, fast LA stock, 20-day custom |

| Ultra-budget stopgap | India | Lowest cost, acceptable for dry herb |

Summary for buyers

American pieces elevate prestige but tie up capital. Chinese glass delivers margin and reliable QC—my pick for 90 % of shops. Indian glass fills the bargain shelf but demands higher reject rates. Tailor your mix, then review sales velocity every quarter.

Next Steps

- 📥 Get a Quote – OEM or stock (sales@cloverpipe.com)

- 📦 Request Free Samples – just cover freight

- 📄 Download Spec Sheet + Temp Chart

- 🤝 Book an LA Warehouse Tour – see 10 000 + SKUs live

- 🔄 Photo → Credit After-Sales – zero-risk breakage policy

FAQ

Q1: Why are American bongs so expensive?

Studio labor, rare-earth color rods, and limited runs raise costs into collector territory.Q2: Are Chinese bongs safe to torch?

Most reputable factories use 5–9 mm borosilicate tested at 560 °C; always request stress-test proofs.Q3: How do I mitigate defects in Indian glass?

Order 10 % extra, inspect welds under LED light, and reserve for dry-herb sales only.Q4: What is the fastest OEM timeline from China?

Design to LA delivery can be 30 days if air-freighted; sea freight adds ~15 days.Q5: Which thickness suits daily renters or lounge use?

7 mm strikes the best balance between weight and durability for high-traffic environments.