Why Do Simple Recycler Designs Work Better?

Cleaning, airflow, and performance issues frustrate recycler users. Overbuilt glass looks impressive—but often hits worse and breaks sooner.

Simple recycler designs work better because shorter, cleaner paths preserve airflow, stabilize recycling, reduce drag, and are easier to maintain. In real use—and in our QC tests—fewer bends mean smoother pulls, consistent water return, better flavor, and longer glass life. I’ll explain why, from hands-on testing and years of shipping recyclers to real customers.

When I first started selling recyclers, I believed more tubes meant more performance. After breaking one during a rushed demo—and then testing hundreds more—I learned the opposite. Simpler paths win in daily use.

Why Do Simple Recycler Designs Have Better Airflow?

Simple recycler designs have better airflow because shorter, straighter paths reduce drag and turbulence, delivering smoother pulls with less effort.

Airflow is the first thing users notice. If it feels tight or choppy, everything else suffers—cooling, flavor, and comfort. In recyclers, airflow is dictated by path geometry. Every bend, angle, and junction introduces resistance. Stack too many together and you feel it instantly.

I’ve tested this side-by-side in our factory and again in our LA warehouse before shipments go out. Same glass thickness. Same joint size. Same water level. The only difference? Path complexity. The simpler recycler always pulls easier. Always.

Shorter Paths = Less Drag

Long recycler loops look impressive on a shelf. But air doesn’t care about looks. It cares about distance and friction. Each extra centimeter of tubing adds resistance. Multiply that by multiple loops and you create drag that the user has to fight.

In practice, that means:

- Harder pulls

- Less consistent vapor density

- Faster user fatigue

Turbulence Is the Hidden Enemy

Complex builds create turbulence—air colliding with water at awkward angles. Instead of smooth laminar flow, you get chaotic movement. That turbulence disrupts recycling and kills flavor.

From QC notes we keep internally, recyclers with clean, direct returns show:

- More stable bubbling

- Faster water reset

- Clearer flavor after repeated pulls

Real-World Airflow Check

When I evaluate a recycler, I use a simple test:

- [ ] Dry pull before water

- [ ] Water pull at recommended fill line

- [ ] Consecutive pulls without refilling

If airflow degrades across pulls, the path is doing too much.

Are Complex Recycler Designs Actually Less Efficient?

Yes—complex recycler designs are often less efficient because added tubes increase drag, disrupt recycling balance, and trap reclaim.

Efficiency isn’t about how many loops you can add. It’s about how reliably the recycler does its job—cooling vapor and returning water without stalling.

I’ve seen beautifully intricate recyclers fail this test. They recycle once. Then stall. Or recycle unevenly. Or clog faster than expected.

Over-Engineering Hurts Consistency

Every recycler needs balance:

- Air intake

- Water volume

- Return speed

Complex builds make that balance fragile. A slight change in water level—or user pull strength—throws everything off.

More Tubes = More Failure Points

Each weld and junction is a stress point. During shipping, cleaning, or temperature changes, these areas take the most strain. From a durability standpoint, simpler designs survive real-world use better.

In our after-sales records, complex recyclers generate:

- More “not recycling” complaints

- More cleaning-related breakage

- Higher return risk

Efficiency From a User’s Perspective

Efficiency means:

- Less effort per hit

- Stable recycling every pull

- Minimal maintenance

On that checklist, simpler recyclers outperform more often than not.

How Does Recycler Path Length Affect Performance?

Recycler path length directly affects drag, cooling efficiency, and recycling speed—shorter paths usually perform better.

Path length is one of the most misunderstood factors. Many assume longer paths mean more cooling. In theory, yes. In practice, not always.

Cooling vs. Resistance Trade-Off

Cooling happens through surface contact and time. But if path length adds too much resistance, users pull harder. Harder pulls increase temperature and negate cooling benefits.

From our internal testing:

- Shorter paths + moderate water volume = smoother, cooler hits

- Excessively long paths = hotter vapor due to forced pulls

Path Length and Recycling Speed

Recycling relies on momentum. If the return path is too long or angled poorly, water loses energy and stalls. This leads to:

- Partial recycling

- Water pooling

- Inconsistent hits

Practical Guideline I Use

When reviewing OEM designs, I follow this rule of thumb:

Yes—simpler recyclers recycle water more consistently because gravity and airflow work together, not against each other.

Recycling consistency is what separates a good recycler from a frustrating one. It’s also where simple designs shine.

Gravity Matters More Than Complexity

Water wants to fall. Simple designs respect that. Direct returns let gravity do the work. Complex upward loops fight physics.

When gravity assists recycling:

- Water returns faster

- Bubbling stays stable

- Less user technique is required

Fewer Variables, Better Results

Complex recyclers demand precise water levels and pull strength. Simple ones are forgiving. That’s critical for beginners—and for customers buying online without hands-on demos.

Consistency Over Time

As reclaim builds up, complex paths clog unevenly. Simple paths clog slower and more predictably, making maintenance easier and performance more stable over weeks of use.

Why Are Simple Recycler Designs Easier to Clean and Maintain?

Simple recycler designs are easier to clean because they have fewer bends, wider passages, and less reclaim-trapping surface area.

Cleaning isn’t optional. And if cleaning is hard, users delay it. Delayed cleaning ruins performance and shortens glass life.

Fewer Bends, Less Reclaim

Every bend is a reclaim trap. Complex recyclers hide resin in places alcohol struggles to reach. Simple designs expose more surface area to cleaning solutions.

Safer Cleaning

Over my career, I’ve seen more recyclers break during cleaning than during use. Why?

- Aggressive shaking

- Heat shock

- Tools forced into tight bends

Simple designs reduce these risks naturally.

Maintenance Checklist I Recommend

- [ ] Warm rinse after sessions

- [ ] Weekly alcohol soak

- [ ] Gentle rotation, no shaking

- [ ] Full air dry

Customers who follow this with simple recyclers report fewer cracks and better longevity.

What Should Buyers Look for in a Well-Designed Recycler?

Buyers should look for balanced airflow, short return paths, even welds, and designs that prioritize function over decoration.

Whether you’re a consumer or stocking a shop, this matters. Good design sells better—and comes back less often.

Key Design Checks

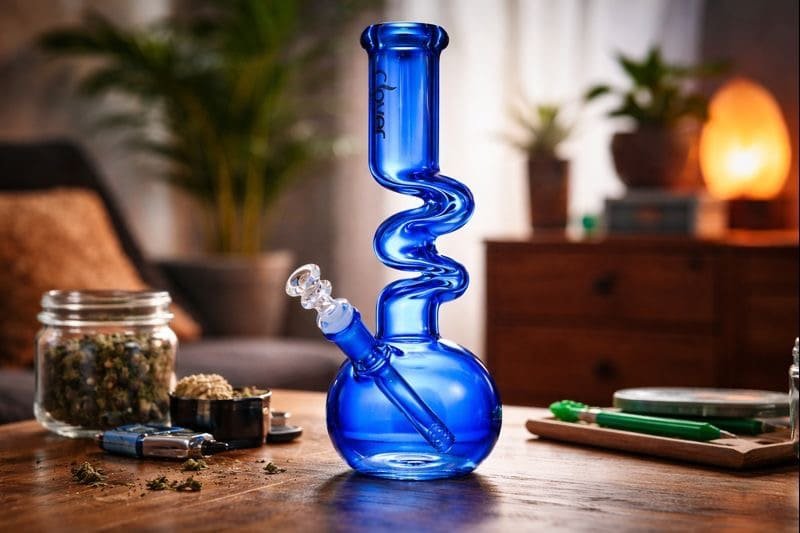

- Straightforward recycling path

- Consistent tube diameter

- Reinforced joints at stress points

- Stable base and balanced weight

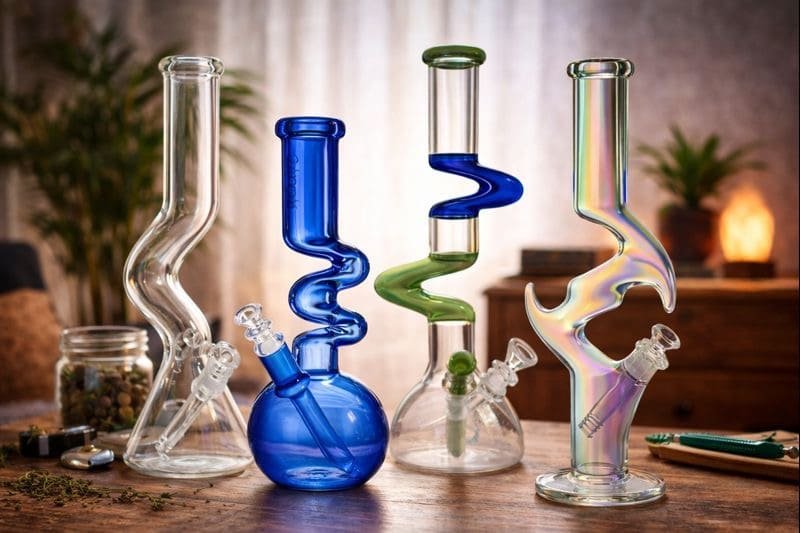

Red Flags I Watch For

- Excessive looping without purpose

- Very thin return arms

- Designs that only recycle at one exact water level

Buying With Confidence

At CloverGlass, we test recyclers for:

- Airflow consistency

- Recycling stability

- Cleaning tolerance

We stock inventory in our LA warehouse so customers can get fast replacements if needed. For OEM projects, our lead time is typically 20–25 days, and we share real performance feedback—not just renderings.

Conclusion

Simple recycler designs work better because they respect physics, airflow, and real-world use. They hit smoother, recycle more reliably, clean easier, and last longer.

From a retail and wholesale perspective, simpler recyclers also reduce returns and support requests. That’s why I recommend them to first-time buyers and experienced users alike.

Next steps:

- Get wholesale quote

- Order Online: https://cloverglasspipe.com/order-glass-smoking-products-online/

- Email Frank: Frank@CloverPipe.com

FAQ

Q1: Are simple recyclers better for beginners?

A1: Yes. Simple recyclers are more forgiving with water levels and pull strength, making them easier for beginners to use and maintain without frustration.

Q2: Do complex recyclers cool vapor better?

A2: Not always. Extra tubes can increase drag, forcing harder pulls that reduce effective cooling.

Q3: Why does my recycler stop recycling?

A3: Overfilling, reclaim buildup, or overly complex path design often disrupt recycling balance.

Q4: Are simpler recyclers easier to clean?

A4: Yes. Fewer bends mean alcohol reaches more surface area and removes reclaim faster.

Q5: Do simple recyclers last longer?

A5: Generally yes. Fewer stress points reduce breakage during cleaning and transport.

Q6: Does glass thickness matter more than design?

A6: Both matter. Thick glass helps durability, but poor design still hurts performance.

Q7: Can simple recyclers still look premium?

A7: Absolutely. Clean lines and balanced proportions often age better than overworked designs.

Q8: Are simple recyclers cheaper?

A8: Often, but not always. Quality materials and skilled glassblowing still matter.

Q9: Do shops prefer simpler recyclers?

A9: Many do, because they generate fewer returns and are easier to explain to customers.

Q10: How do I choose the right recycler?

A10: Focus on airflow, stability, and ease of cleaning—not just how complex it looks.