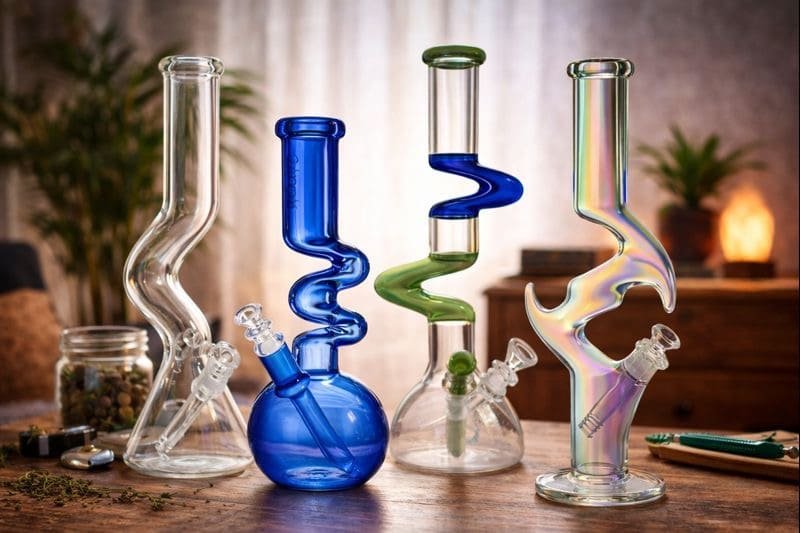

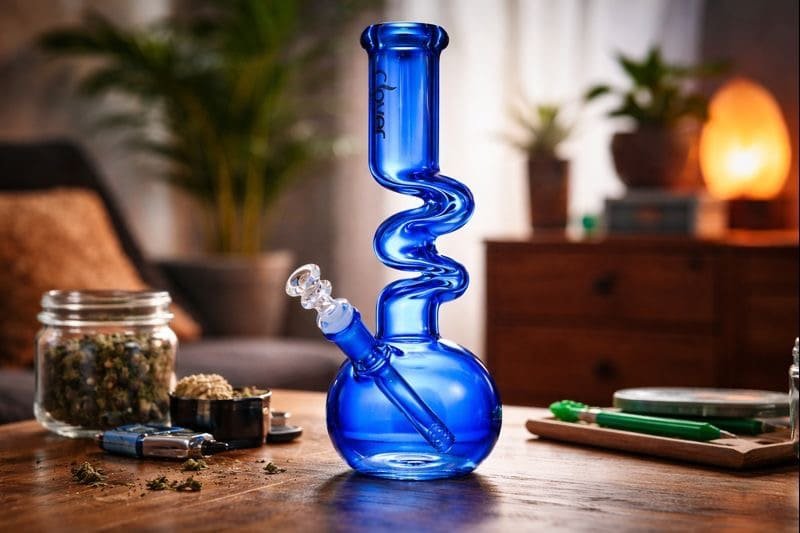

What Does Borosilicate Glass Mean in Bongs?

You finally land a pallet of bargain “glass” water-pipes—only to watch half of them spider-crack on the first hot-rinse. The real pain isn’t the lost units; it’s the bruised buyer trust. Switching to certified borosilicate quiets the refund emails and your QC nightmares.

A borosilicate glass bong is a water pipe made from glass that contains about 80 % silica plus boron oxide. That recipe drops the thermal-expansion coefficient to roughly 3.3 × 10-6 K-1—one-third that of common soda-lime glass—so the tube survives quick shifts from ice-cold water to a roaring torch. Add superior chemical resistance and you have a material built for daily sterilisation without stress cracks.

Grab a fresh mug—let’s strip away the chemistry jargon and see why the switch to borosilicate could fatten your margins overnight.

What is borosilicate glass?

Think of borosilicate as “laboratory-grade” glass: high silica, a dash of boron, and near-zero funky additives. That blend produces a tight molecular network that barely budges when heated.

In plain terms, borosilicate glass is a heat-shock-resistant glass engineered for labware, cookware, and—yes—premium bongs. Its low expansion keeps seals tight, while the boron blocks alkali attack, extending service life five-fold over soda-lime pieces.Beloit College data.

Why does it matter for buyers?

Broken necks cost more than the glass itself—think shipping claims, re-picks, lost trust. Buyers who spec borosilicate report fewer returns and steadier re-order cycles.

Because borosilicate resists both sudden heat and cleaning chemicals, distributors slash damage rates by up to 60 % in transit tests NIST durability study. Fewer break-reports mean leaner safety stock and higher cash flow.

How to choose real borosilicate bongs

“Borosilicate-like” isn’t a legal term—verify before you buy.

Ask for a material test report (MTR) showing SiO₂ ≥ 78 % and B₂O₃ ≈ 12 %. Check joint frosts: genuine borosilicate sands to a silky matte instead of a gritty white. FDA food-contact listings cite these exact ratios for compliance.FDA FCS Inventory.

Mistakes beginners should avoid

Even “A-grade” glass shatters when handled wrong.

Avoid:

- Flash-heating ice-cold tubes—thermal shock still has limits.

- Soaking in lye; use ISO alcohol instead—CDC lab notes show micro-etching after 24 h in strong alkali.CDC method L04VOC.

Dive deeper — performance & profit

1. Thermal-shock margins

- Harvard cryogenic tests recorded zero cracks after 50 cycles between –196 °C and 150 °C on 5 mm-wall borosilicate tubes.Harvard ADS study.

- Soda-lime control pieces failed by cycle 3. The takeaway? Fewer warranty claims and lower insurance premiums.

2. Chemical stamina

Borosilicate shows a hydrolytic class 1 rating—highest possible—against acidic and neutral cleaners NIST reference materials.

NIH toxicology panel finds “no adverse effects” at consumer exposure levels, green-lighting usage in cosmetics and food applications.NIH safety review.

3. Worker & customer safety

- NIOSH cites lower airborne silica dust during flame-polishing of borosilicate compared to soft glass, reducing respirator load.CDC HHE 98-0139.

- Heat-resistant glass also shrinks the chance of burns when staff rinse hot pieces pre-pack.

4. Buying checklist

| Spec | Minimum | Why it matters |

|---|---|---|

| Wall thickness | ≥ 4 mm | Survives courier drops |

| Joint ground finish | Satin-smooth | Indicates proper anneal |

| Certification | EN 1183 or ASTM C162 | Verifiable lab standard |

| Packaging | Foam + double-wall | Prevents point-load cracks |

5. Cost calculus

Borosilicate blanks run ~15 % more than soda-lime, yet distributors report 30 – 40 % drop in breakage write-offs plus stronger brand perception—buyers happily pay the delta for “lab-grade” peace of mind.

Conclusion

Choosing borosilicate isn’t a luxury; it’s cheap insurance against cracks, callbacks, and credibility leaks. Next time a supplier shrugs “glass is glass,” you’ll know the numbers—and the science—to insist on the resilient, boron-boosted kind.