How Do I Find Reliable Wholesale Glass Pipe Suppliers?

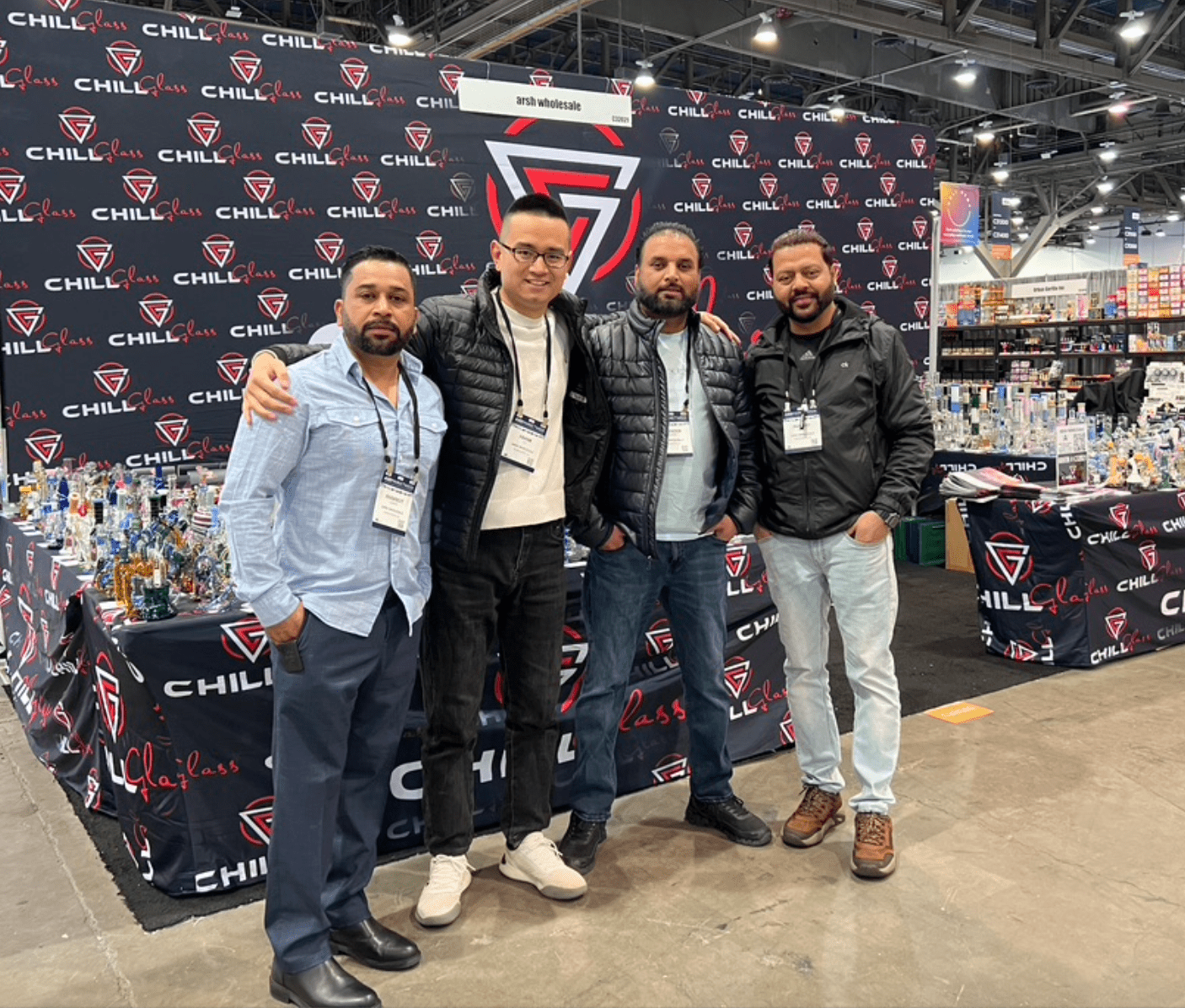

Meeting suppliers face-to-face at trade shows builds trust and reveals true capabilities

Table of Contents

What Should You Look for in a Wholesale Glass Pipe Supplier?

Dive Deeper:

- Material & Craftsmanship: Insist on premium borosilicate and veteran lampworkers.

- Capacity & Lead Time: Ensure the factory can handle your volume with reliable delivery (20–25 days OEM).

- Communication: Fast, transparent replies—ideally with an English‑speaking account manager.

- After‑Sales Support: Photo-to-credit breakage guarantee and US warehouse restocking (3–7 day delivery) safeguard your business.

- Certifications & Compliance: Check for lab reports, FDA/CE compliance, and customs clearance expertise.

Where Can You Source Reliable Suppliers?

🏢 Trade Shows

- Meet decision-makers directly

- Inspect product samples

- Compare multiple suppliers

- Build personal relationships

💻 Online Marketplaces

- Alibaba Gold Suppliers

- Global Sources verification

- Transaction history review

- Third-party audits

🌐 Industry Networks

- Facebook industry groups

- LinkedIn connections

- Trade associations

- Peer referrals

📹 Virtual Factory Tours

- Live video tours

- Production line inspection

- Quality control verification

- Equipment assessment

Dive Deeper:

- Trade Shows: Face-to-face meetings reveal factory scale and professionalism.

- Online Marketplaces: Filter for Gold Suppliers with high transaction histories and onsite audits.

- Industry Networks: Ask B2B peers in Facebook groups or LinkedIn for recommendations.

- Local Visits (or Video Tours): Request live factory walkthroughs to validate production lines and quality controls.

How Can You Verify a Supplier's Capabilities?

| Verification Method | What to Check |

|---|---|

| Sample Orders | Order 5–10 units to check build quality, fit, and finish. |

| Factory Audits | Review standard operating procedures, material sourcing, and annealing processes. |

| Third‑Party Testing | Request lab reports for heavy metals and thermal shock resistance. |

| Reference Checks | Contact existing clients for honest feedback on lead times and after‑sales. |

Dive Deeper:

- Sample Orders: Order 5–10 units to check build quality, fit, and finish.

- Factory Audits: Review standard operating procedures, material sourcing, and annealing processes.

- Third‑Party Testing: Request lab reports for heavy metals and thermal shock resistance.

- Reference Checks: Contact existing clients for honest feedback on lead times and after‑sales.

CloverGlass Factory workshop

How Can You Build a Lasting Partnership?

Dive Deeper:

- Forecasting & Planning: Share your sales projections to help the factory allocate capacity.

- Co‑Development: Collaborate on monthly new drops and OEM projects to stay ahead of trends.

- Regular Reviews: Hold quarterly calls to discuss quality metrics, delivery performance, and design updates.

- Transparent Issue Resolution: Use structured escalation paths for any breakage, delay, or compliance issue, reinforced by clear policies.

Building long-term partnerships requires transparency and mutual trust

Conclusion

Finding reliable wholesale glass pipe suppliers requires targeted research, thorough verification, and relationship-building. By focusing on material quality, capacity, communication, and after‑sales safeguards—and leveraging trade shows, online platforms, and samples—you'll secure partners who drive your business forward. At CloverGlass, I've refined this process over 11 years to protect margins and ensure seamless supply.

Ready to partner with a dependable supplier?

Let CloverGlass be your trusted wholesale glass pipe partner

Frequently Asked Questions

What's the best way to vet a glass pipe supplier?

How can a US warehouse benefit wholesale buyers?

Why attend trade shows for supplier sourcing?

What should be included in an after‑sales policy?

How does co‑development strengthen supplier relationships?

Explore More Content

Quick navigation to other sections for the complete purchasing guide

What Are Glass Bongs? (Definition & Parts)

Learn the anatomy—base, neck, bowl, downstem, perc—so you can read spec sheets fast and avoid mismatched components.

→ 2Why Source Glass Bongs from China?

Craftsmanship + scale = better margins. See why Chinese factories lead on SKUs, speed, and cost efficiency.

→ 3Types of China Glass Bongs

Beaker, straight tube, recycler, dab rigs—match each style to your buyer persona and bundle smartly.

→ 4Manufacturing Process in China

From borosilicate tubing to annealing and QC steps—understand the process to negotiate specs and tolerance.

→ 5Key Factors When Buying Wholesale

Thickness, joint sizes, MOQ, packaging. These details decide your landed cost and customer satisfaction.

→ 6Pain Points & Solutions (B2B)

Breakage, customs, old designs—real problems, practical fixes. Set policies and avoid drama.

→ 7How to Choose a Reliable Factory

Checklist: capacity, OEM ability, trade‑show creds, warehouses, after‑sales. Vet fast without missing red flags.

→ 8Logistics & Fulfillment

Lead times, FCL/LCL, overseas stock. Plan shipping windows and keep cash flow smooth.

→ 9Custom Branding Opportunities

Logos, color prints, boxes, media packs—turn commodity SKUs into a brand shops ask for by name.

→WhatsApp us

Get 10% Off Your First Order

Perfect for retail buyers and small wholesale orders.

Subscribe to receive exclusive discounts, new arrivals,

and restock updates from CloverGlass.