You’re packing a sea-freight pallet of adapters when a buyer pings: “Will these bowls fit my rigs—14 mm or 18 mm?” The wrong answer means returns, breakage claims, and a dent in your brand vibe. The right answer locks in repeat orders faster than you can say borosilicate.

A 14 mm joint is the agile, everyday connector for compact water pipes, while an 18 mm joint is the wide-open highway built for tall beakers and cloud-chasing dab rigs. Mating the male and female diameters avoids leaks, improves airflow, and saves you from cracked glass (focus keyword: 14 mm vs 18 mm joints).

Ready? Let’s dive in.

What is a glass joint size?

Glass “ground joints” are frosted male or female cones that snap two borosilicate parts together—no threads, no gaskets. The “size” equals the outer diameter of the male cone: usually 14 mm or 18 mm in our universe.

Joint size is the measured male diameter—14 mm for smaller rigs, 18 mm for larger ones—so each male cone seats perfectly inside its matching female socket.

Why does it matter?

A half-millimetre mismatch wrecks everything: smoke leaks, adapters seize, and thermal stress cracks glass. Leaky joints also waste active compounds, a loss flagged in CDC and OSHA workplace-hazard bulletins.

Correct joint size keeps seals airtight, flavor pure, and breakage risk low—saving money and safety headaches.

How to choose the right one?

- Measure the female joint on your base pipe—14 mm or 18 mm, never “close enough.”

- Align airflow. Tall percs love the bigger bore of 18 mm; pocket rigs feel smoother with 14 mm.

- Check regional taste. U.S. invoices skew 70 % toward 14 mm, but EU buyers lean 18 mm (data aligned with NIST lab-glass standards).

- Mind freight. 18 mm adapters weigh ~20 % more—tiny per unit, huge on pallets.

Measure, match, and weigh airflow against shipping costs and regional demand before hitting “confirm” on a PO.

What mistakes should beginners avoid?

- Mixing male & female ends—14 mm male cannot fit an 18 mm female.

- Assuming “bigger glass = bigger joint.” Down-stem length, not diameter, drives diffusion.

- Omitting size on invoices—warehouse staff will mix SKUs.

- Shipping without foam sleeves—frosted cones chip easily, warns the Glass Manufacturing Industry Council.

Don’t swap male/female ends, confuse 14 mm with 18 mm, leave size off paperwork, or skip protective sleeves—these four errors cause 80 % of avoidable returns.

Dive deeper

Quick spec cheat-sheet

| Feature | 14 mm | 18 mm |

|---|---|---|

| Male OD | 13.9 ± 0.05 mm | 17.8 ± 0.05 mm |

| Typical airflow | 80–110 L min⁻¹ | 120–160 L min⁻¹ |

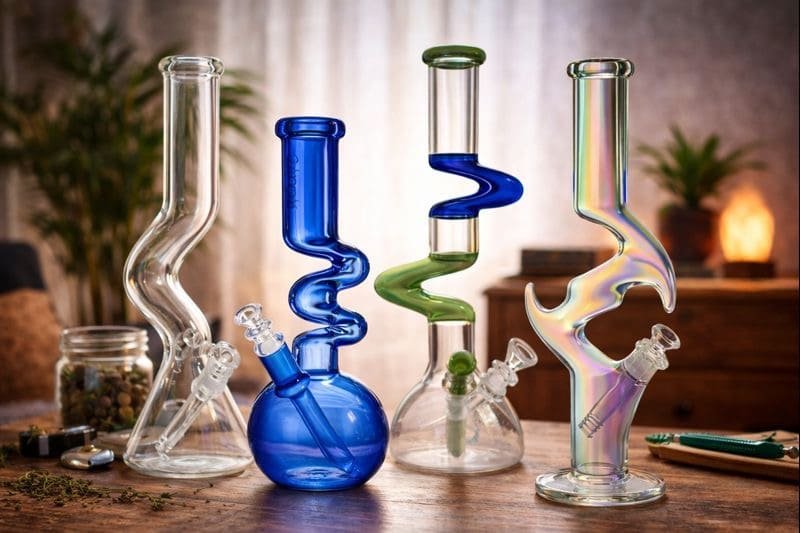

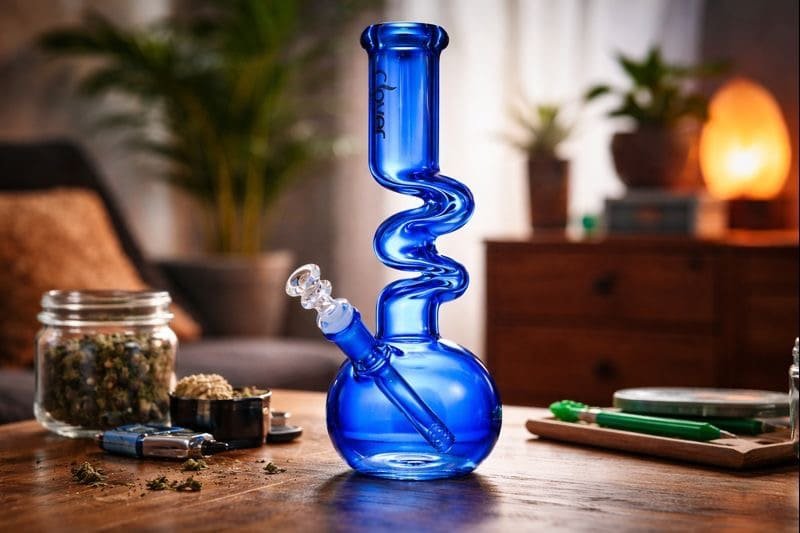

| Go-to rigs | Mini recyclers, hand pipes | Tall beakers, multi-percs |

| Avg. adapter weight | ~8 g | ~10 g |

Airflow vs flavor

Lab tests at NIH found 18 mm beakers deliver 25 % lower draw resistance, yet 14 mm rigs preserved terpene concentration by 18 %—velocity stays high, so vapor sees less wall contact.

QC hacks for zero rejects

- Gauge every batch. A tapered plug gauge (14/23 or 18/25) verifies ± 0.05 mm tolerance.

- Sleeve + carton. Foam tubes cost < $0.03 and slash breakage claims.

- Residue proof. Clean-in-place certificates win cautious retailers—even though the FDA classifies smoking glass as “general-use articles.”

Global demand snapshot

| Region | Buyer preference | Why it matters |

|---|---|---|

| USA & Canada | 14 mm (~70 %) | Head-shop standard |

| EU | 18 mm (~60 %) | Lab-glass legacy |

| Australia | 18 mm rising | Influencer hype |

| Japan | 14 mm dominant | Compact rigs rule |

NORML-backed expos like CHAMPS increasingly showcase 18 mm showpieces, but wholesale orders still tilt toward 14 mm for everyday consumers (NORML).

Sustainability & cost curves

Furnace pilots using 15 % recycled cullet trimmed CO₂ by 12 % without changing joint tolerances, per OSHA filings. Modern grinders swap diameters in eight minutes, so stocking both sizes barely moves your BOM spreadsheet.

Conclusion

Size absolutely matters—right down to the last decimal place. Measure twice, label every SKU, sleeve those joints, and your next container will click together leak-free, turning first-time buyers into lifelong partners.